Common Materials List for Molding

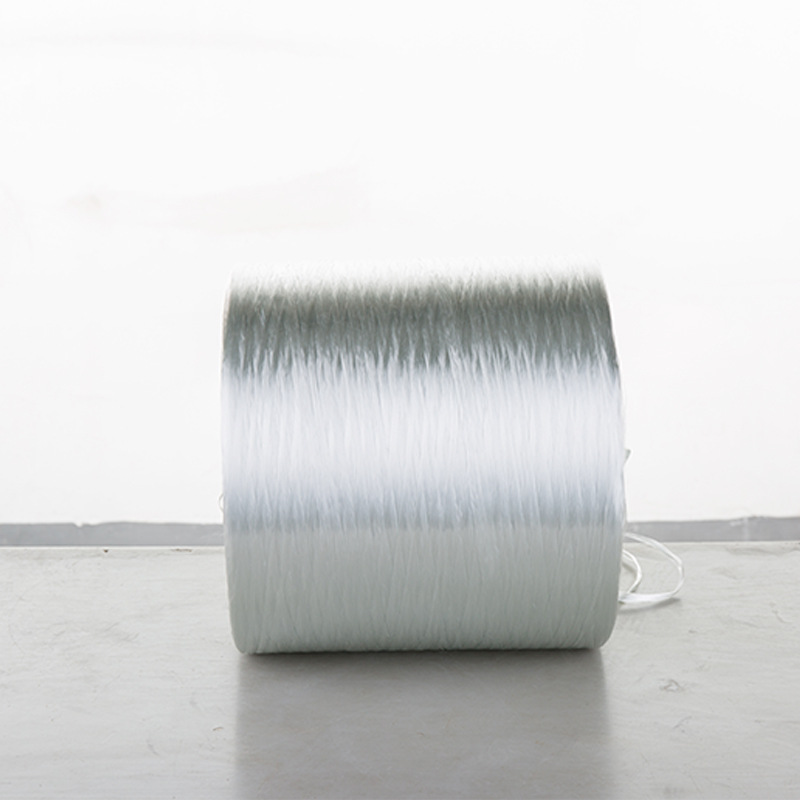

Fiber Reinforced Plastic

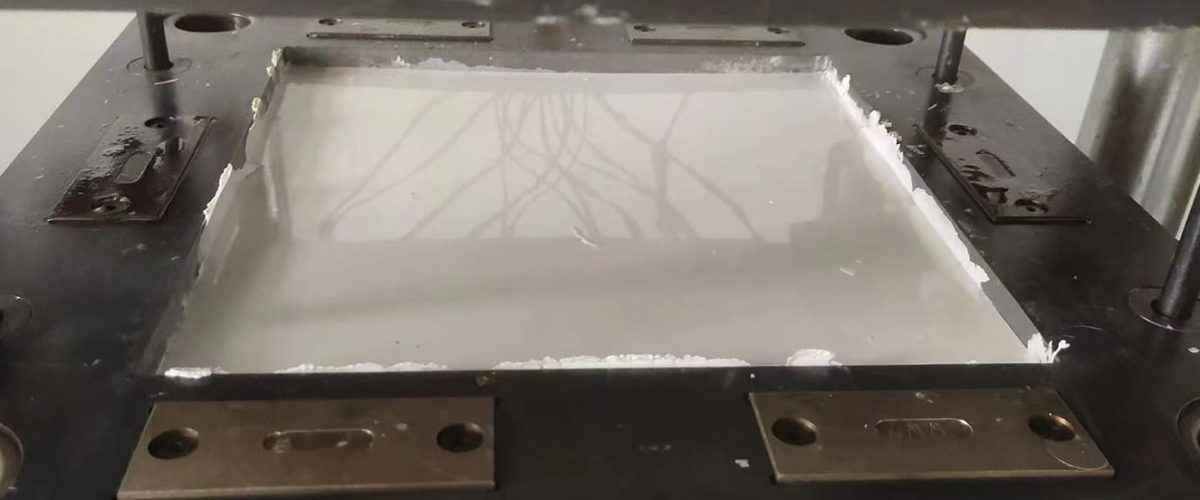

Introduction to Compression Molding

Compression molding can be categorized based on the type of material used: sheet molding compound (SMC), bulk molding compound (BMC), thick molding compound (TMC), and wet lay-up compression molding. The process utilizes heated metal molds mounted in large hydraulic presses and can be automated for improved efficiency.

Compression molding offers design flexibility, allowing for features such as inserts, ribs, bosses, and attachments. It also achieves good surface finishes, reducing the need for extensive post-processing and lowering finishing costs. Additionally, compression molding minimizes trimming and machining operations, further reducing labor expenses.

BMC/SMC Resin

for Bulk/Sheet Molding Compound

Low Profile Additive

for Bulk/Sheet Molding Compound

Auxiliary

for Compression Molding

Product Consultation

Scheduling An Appointment

Please let us know if you have any questions!